What is Toyo-Sasaki Glass HS Series and How to Choose the Right One for your needs?

- Toyo-Sasaki Glass (TGS) – one of the most trusted glassware brands in Japan, lauched the HS series since 1967. It is known as HS (Hard Strong) Series

- The HS series represents the pinnacle of durability and design in glassware, with total sales exceeded 800 million as of 2017

- HS referring to Japan’s toughened glassware with reinforced rims made from soda-lime glass.

As mentioned in our previous post, Japan was among the first countries to implement rim reinforcement tempered glass – unlike most countries that reinforce the entire glass body. According to Seiichi Kimoto, this technique served as a kind of non-tariff barriers that limited the import of glassware from other countries.

In this post, we will dive deeper into the unique, standardised glasses from Japan - especially how Sasaki Glass developed this legendary series. We will also explain how to differentiate between the labels within the HS series.

What Determines the Toughness of a Glass?

To begin with, we need to know how are the three factors that determines the toughness of glasses: 1) the Thickness of Rim, 2) Rim Top Finish and 3) Composition of Glass.

Thickness of Rim Top

The thickness of rim determines how smoothly water or beverages flow from the glass to the month. At the same time, the rim is where glassware often experiences the most damages during daily use. Nowadays, glass designers fine-tune the thickness – adjusting it by as little as 0.01mm to balance strike the perfect balance between smoothness and toughness.

Rim Top Finish

There are two common rim finishing methods:

- Burn-off (Hot Cut): the rim is cut while the glass is still hot. This method leaves a clean edge and induces a compressive stress layer, which strengthens the rim.

- Cold-cut (Diamond Cut): This method uses a diamond tool to cut the glass once it’s cooled, which cam leave microscopic cracks that weaken the rim over time.

Generally, the burn-off method results in a stronger finish than cold-cut finishes, due to the microscopic fractures created by the diamond cutter. However, the burn-off method can never achieve the same level of refinement as a cold-cut finish.

Composition of Glass

- Soda-lime glass (used in the HS Series): Made of silica, soda ash, and limestone. It's cost-effective and more durable. It can also be tempered to increase strength by up to 3 times.

- Crystal glass: Contains metallic oxides and offers greater clarity and brilliance, making it suitable for intricate designs. However, it’s more fragile and prone to scratching and chipping.

Now that we have the basic understanding of toughened glass, we can understand how companies like Toyo-Sasaki Glass tries to use different techniques to enhance those factors.

Tempering Method - Widely Used, Cost Effective

The method involves first heating the glass to around 620–650°C until it becomes soft, then rapidly cooling it with blasts of cold air. This quick cooling causes the outer surface to harden faster than the inner layers, creating a tension-compression balance within the glass. As a result, tempered glass becomes much stronger and more resistant to impact and thermal shock. If it does break, it shatters into small, blunt pieces instead of sharp shards, making it safer for everyday use.

Ion Exchange Method – Premium and High-Precision

Ion exchange is a chemical strengthening process used to make glass more durable. In this method, the glass is soaked in a hot bath of potassium salt (usually potassium nitrate) at around 400–450°C. During this soak, smaller sodium ions in the glass surface are replaced by larger potassium ions from the bath. Because the potassium ions take up more space, they create a layer of compressive stress on the surface of the glass. This makes the glass significantly stronger and more resistant to scratches, cracks, and thermal shock. Unlike tempering, ion exchange doesn’t change the shape or clarity of the glass, making it ideal for thin or delicate designs.

Finally, let’s explore how Toyo-Sasaki has crafted its mouth-reinforced tumblers and how did it make the non-tariff barriers for a long period of time. The tempering process for the rim requires precise control of heating and cooling, allowing each glass to achieve enhanced durability without sacrificing the refined look and feel of thin glassware. To be more specific, if glass was heated up beyond the strain point and cooled down rapidly during the tempering process, the significant tension added to the glass would result them to violently break, throwing tiny shards across the room and even into people’s hands. This is why rim tempering can isolate the strength of the glass and prevent large failures when glass does ultimately chip. (Check your tumblers and see if you can notice any rim treatments!)

With their advanced technology and TSG’s leading position in the tempered glass industry, they divide their products into three distinct taughtened glass labels – so that everyone can find their ideal drinkware. Let’s finally introduce the three labels – HS Blue, HS Gold and HS Platinum.

HS Blue

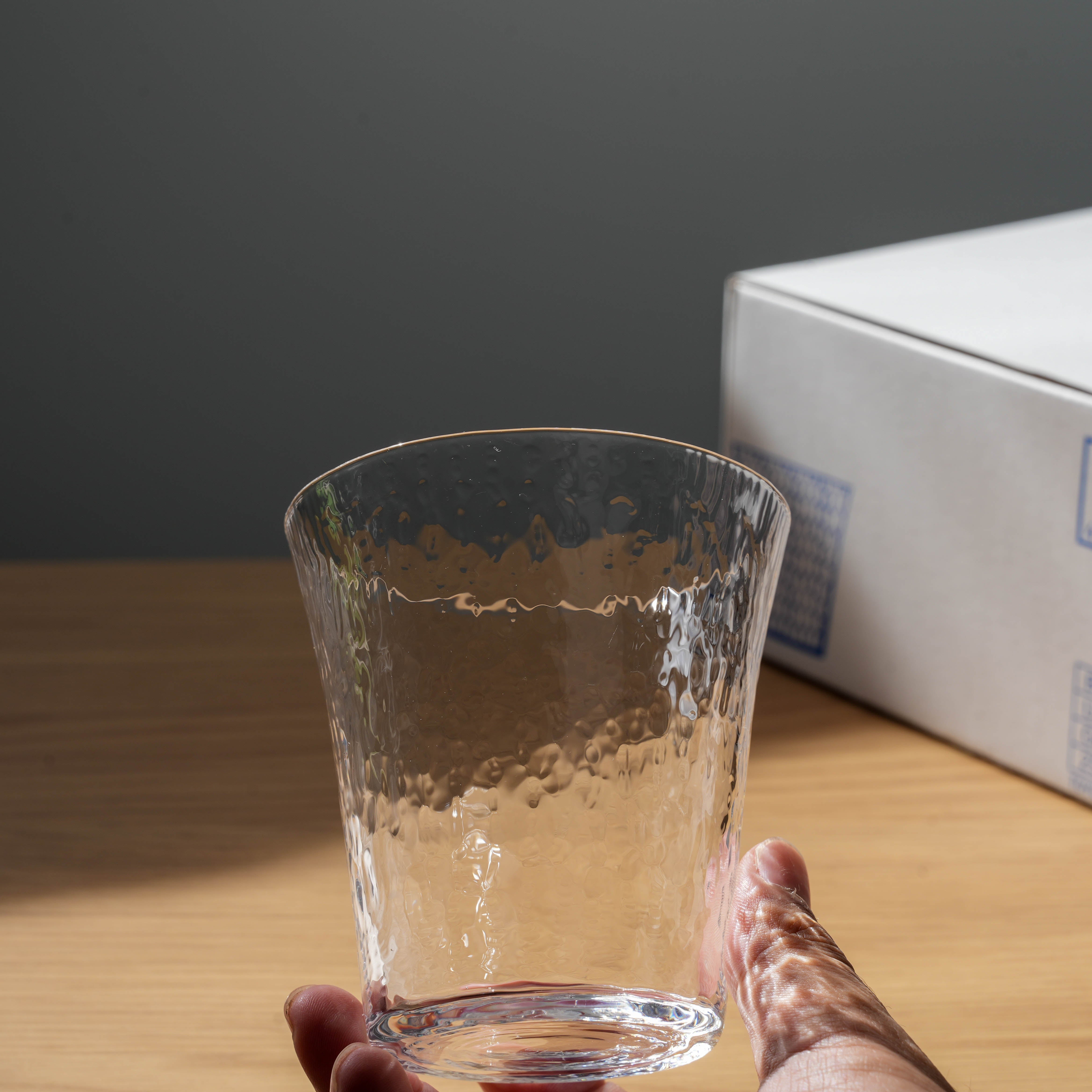

This label features Top Edge Toughened using the Tempering Method, offering the highest level of impact resistance at rim. Our favourite HS Stackable Tumblers below are a perfect example of this Label. If you look closer at the rim, you will notice that the burn-cut lip is slightly separated from the body. The smooth and thick rim not only enhances comfort but also protects the glass from damage – especially when stacking or during regular use.

More importantly, for HS Blue, the simple and down-to-earth design makes them blend seamlessly into any household. From industrial style to minimalism, these tumblers can match just about everything.

If you are someone who likes feeling the weight of an object in your hands, these glasses are the best fit. With a thickness of 1.8mm or above, making it the thickest within the HS series. This gives them a solid, reassuring presence in your hand, making you feel both safe and comfy,

HS Gold

Similar to HS Blue, the HS Gold label also features a mouth-toughened compressive layer that protects the glass from scratches and impacts over time. The key difference lies in the design. HS Gold glasses have bolder, more elegant silhouettes compared to HS Blue, making them especially popular in upscale restaurants and hotels. The cold-cut rim adds a refined touch, making them ideal for serving cold beverages, wine, or water. While their design may feel slightly more elaborate, they are perfect for us when we want to impress our guests at home and pair them with our home-made gin and tonic. ☺

HS Platinum

Finally, the HS Platinum label - the thinnest and lightest in the HS series and the most irresistible label that everyone loves – is made using the Full-Surface Ion Exchange Method for durability and strength. They are only between 1.1 mm to 1.4mm thin (it basically feels like paper when you are holding them) yet they are 1.5 times stronger than non-strengthened glass, confirmed by an industry-standard steel ball drop test. (You can find the video of this test below, where they used HS Usurai Tall Glass).

Finally, the HS Platinum label - the thinnest and lightest in the HS series and the most irresistible label that everyone loves – is made using the Full-Surface Ion Exchange Method for durability and strength. They are only between 1.1 mm to 1.4mm thin (it basically feels like paper when you are holding them) yet they are 1.5 times stronger than non-strengthened glass, confirmed by an industry-standard steel ball drop test. (You can find the video of this test below, where they used HS Usurai Tall Glass).

HS Platinum are simply the first choice for high-end hotels and restaurants, not only because of the award-winning design (Fino Range – winner of the Good Award in 2017), but also for their excellent resistance to scratches. The image below explains it perfectly. A practical use test was conducted at a restaurant in Tokyo, to evaluate the surface corrosion resistance for the HS Platinum label, where the glass experienced frequent dishwashing and glass-to-glass contact. The photo on the left shows undoubtedly that HS Platinum has such strong scratch resistance that they stay new and shiny.

In other words, HS Platinum is the piece that would bring you an intimate experience with human ingenuity and authenticity.

_________________________________________________

After all this research into modern technology and machine-made glasses, I cannot help but wonder - what is it that makes people still appreciate handmade or mouth-blown glass, even when machine-made options excel in so many ways?

I look forward to starting my research and have my next blog about handcrafted glassware, such as Edo Glass, in search of an answer to that very question.

Finally, I hope this post helps you find your perfect tumbler or glassware! Thanks for reading ☺